The working principle of the orbital motor is something that has been widely discussed and studied by scientists and researchers in recent years. This mechanism is used in a variety of industrial applications, including heavy machinery, agricultural machinery, and even automobiles.

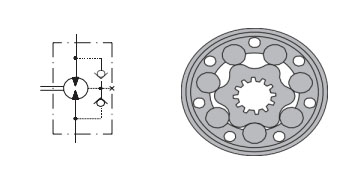

At its core, the orbital motor is a hydraulic motor that operates by converting fluid pressure into mechanical energy. It is composed of two parts – an inner rotor and an outer stator. The rotor, which is connected to the output shaft of the motor, rotates around a fixed center. The stator, on the other hand, is stationary and provides the housing for the rotor.

When fluid is introduced into the motor, it flows through various channels and passages that are designed to create a series of pressure differentials. These differentials result in a force being applied to the rotor, which in turn causes it to rotate. This rotation drives the output shaft and hence provides the mechanical energy required for the specific application.

One of the benefits of the orbital motor is that it can operate at very high speeds and under very high pressures. This makes it ideal for heavy-duty applications where traditional motors might struggle to keep up. Furthermore, the design of the motor is relatively simple and requires little maintenance, making it a cost-effective solution for many industries.

Despite its many advantages, the orbital motor is not without its limitations. One of the primary drawbacks is that it can be relatively inefficient compared to other types of motors. This is because the motor relies on the pressure differential created by the fluid to generate torque. As a result, it can be less efficient than other types of motors that use more direct means of generating torque, such as a piston motor.

Despite these limitations, the orbital motor remains a popular choice for a variety of industries. In order to get the most out of this powerful device, it is important to choose the right type of motor for the specific application. This will often require a careful balance of factors, such as speed, pressure, and efficiency, to ensure that the motor performs as intended.

Post time: Mar-27-2023