The first Gerotor motor was produced 65 years ago.

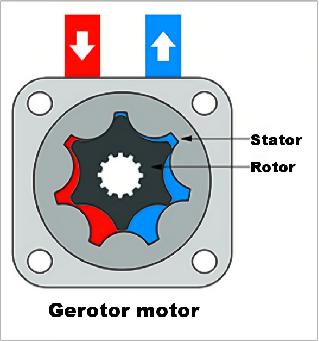

Rotor stator pair, including a stator and a moving planetary gear rotor

Smaller volume, more compact structure, for light and low pressure working conditions,

It does have a loose tolerance, and due to the clearance naturally generated by the assembly of the stator and rotor, the gear cannot be engaged too tightly. These clearances allow more oil to flow from high pressure to low pressure, resulting in greater slip and less switching torque.

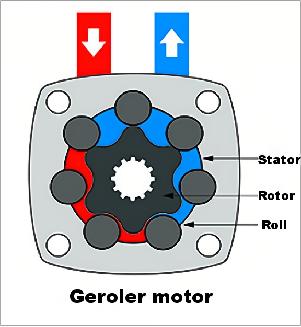

Soon after, the first orbit motor with needle teeth was produced to meet the needs of the market, and its performance and reliability were improved.

This is a major difference between the rotor and stator. The cycloid design of needle teeth does not use the stator plate, but combines the needle teeth to form a pressure chamber.

It is these needle teeth that eliminate the clearance in the cycloidal design to achieve a tighter fit and tighter tolerance, allowing less oil to pass through, so that the gear fits more tightly and eventually converts to greater torque.

The motor with needle cycloid design is stronger, more wear-resistant, and traditionally has a longer service life and better performance; However, these benefits bring additional costs.

The Gerotor motor covers the following series:

OMM and OMP Series

Geroler motors cover the following series:

OMR, OMS, OMT and OMV motor series

(GP series can be made in both Gerotor type and Geroler type.)

Post time: Oct-26-2022