A hydraulic motor converts flow and fluid pressure into rotary motion. It’s the muscle of the hydraulic system.

Before we begin looking at different types of hydraulic motors, it is worth reminding ourselves how hydraulic systems work and the role that a hydraulic motor plays within the overall system.

What is the purpose of a hydraulic motor?

Hydraulic systems are designed to transmit power, in a controlled way, through the use of pressurised liquids. Within a hydraulic system, the hydraulic pump ensures the continued flow of fluid. Pressure can then be created by the careful design of applied forces and the gauge of pipes. The hydraulic motor then converts the kinetic energy of flow and the fluid pressure into rotary motion.

About hydraulic motors

It can be a little confusing to those new to hydraulic systems when we talk about hydraulic motors. They should not be confused with the “prime mover” – the engine that initiates the process by powering the pump. For this reason, you will also hear hydraulic motors referred to as rotary actuators, since this more accurately describes the function they fulfil within the hydraulic system.

There are two different types of actuators in a hydraulic system: rotary actuators (or hydraulic motors) and linear actuators (or cylinders).

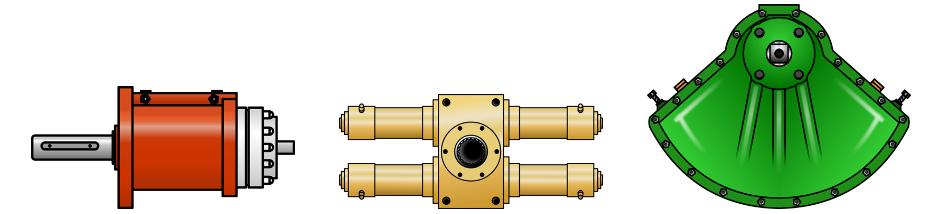

There are also semi-rotary actuators like helical, rack and pinion, and vane actuators, illustrated left to right in the image here.

The factors that will affect your choice of hydraulic motor

Deciding which hydraulic motor is right for your application will depend on a number of factors:

● Speed

● Torque

● Range

● Physical characteristics such as robustness, weight, size, etc.

● Ease of service / maintenance

● Acceptable noise levels

● Compatibility with the other components in your hydraulic system

The benefits of using a hydraulic motor

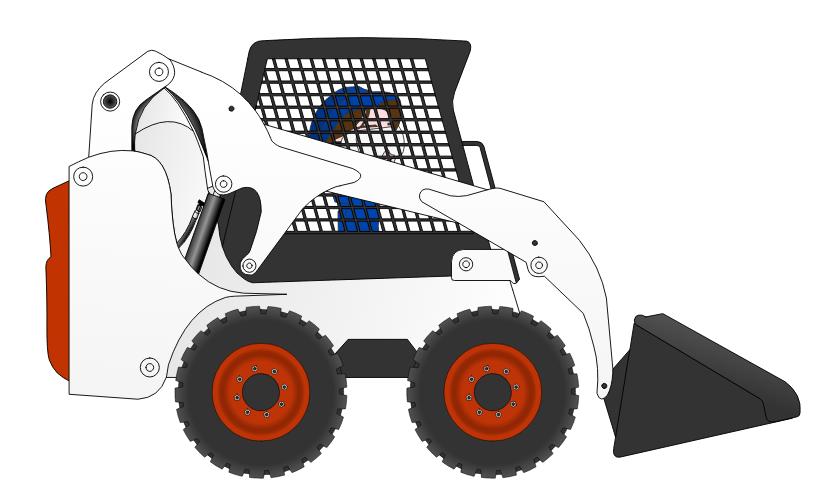

GRH looks at how a hydraulic motor works in order to explain their advantages. Using an industrial construction vehicle to illustrate a typical hydraulic application, it shows how the vehicle’s diesel engine converts the chemical energy of the fuel into rotational energy.

The hydraulic pump then converts the rotational energy into a combination of kinetic and potential energy. Then the hydraulic motor converts the kinetic / potential energy back into rotational energy.

Why are these energy conversions important? Because it makes for greater control and, since most rotary actuators are designed to be bi-directional, it means that reverse motion is possible.

If you would like to learn more about different types of hydraulic motors, Please contact us.

Email: grhsh@grhcn.com

WhatsApp: +0086 18116148343

Post time: Oct-25-2022